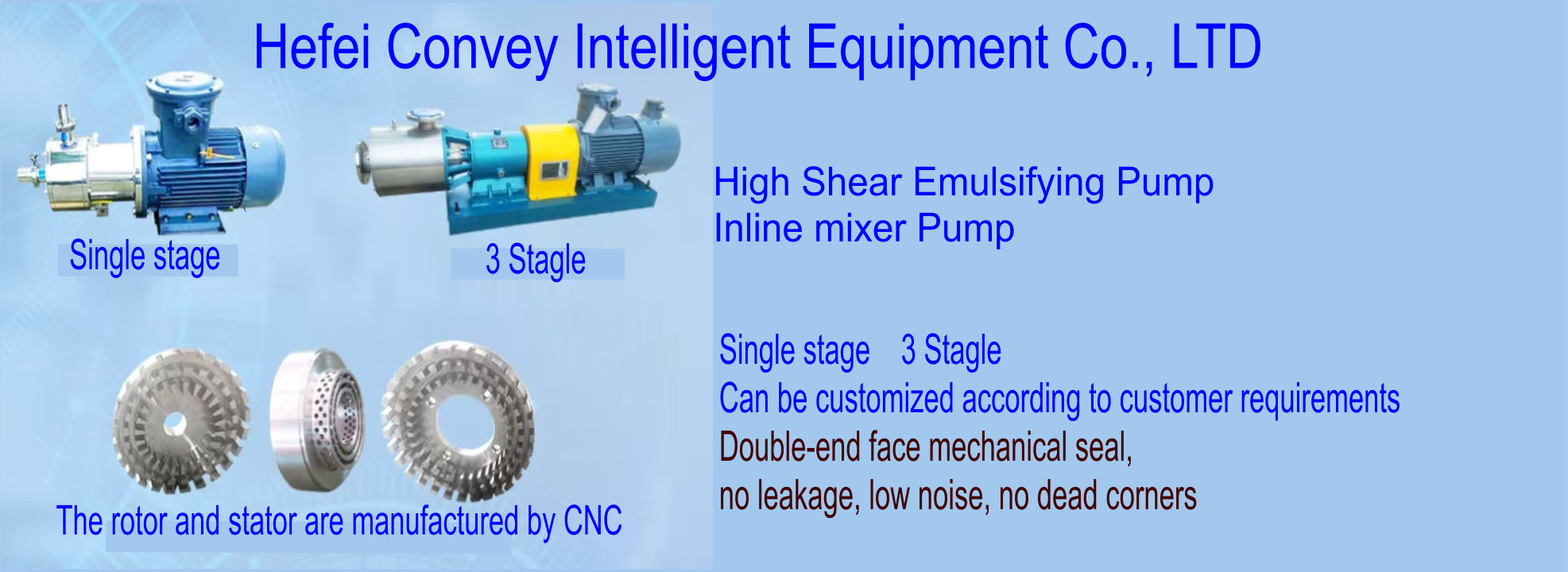

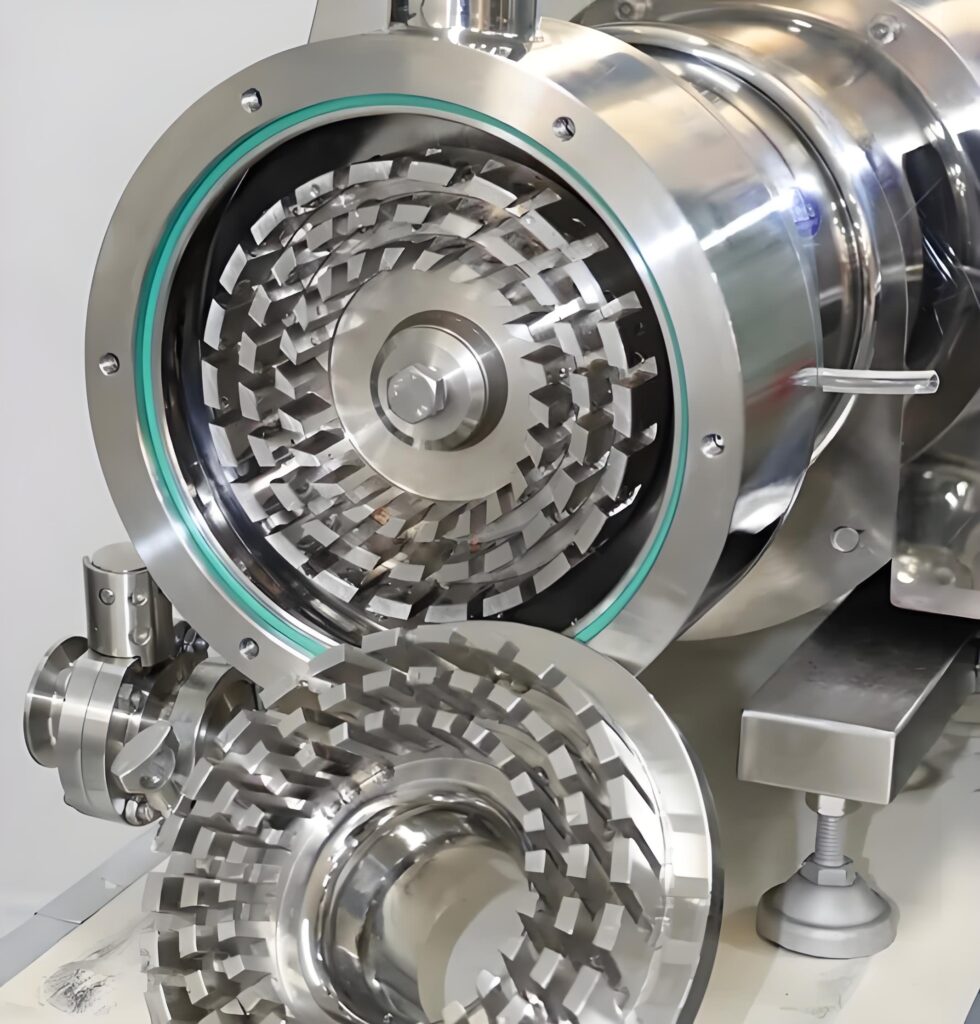

Emulsifying pump

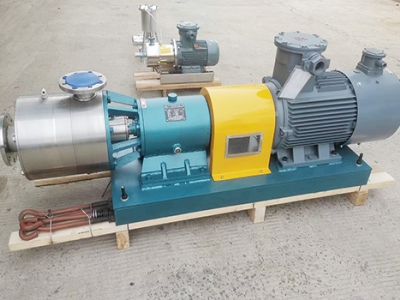

Emulsifying pump, High speed inline mix pump is an industrial device that generates powerful shearing force through the precise combination of the rotor and stator during high-speed rotation to achieve mixing, crushing and emulsification. Its working principle involves high-frequency hydraulic shearing and centrifugal extrusion to evenly distribute and emulsify the materials. Structurally, it is composed of multiple layers of interlocking stator and rotor, made of stainless steel for corrosion resistance, and features small volume and low noise. The functional features include continuous production and design without blind spots, and it is applicable to multiple fields such as daily chemicals, food, and medicine

Dynamic power

Material: Stainless steel

Production type: Continuous

Number of layers: three or more layers

Handling multiphase liquids

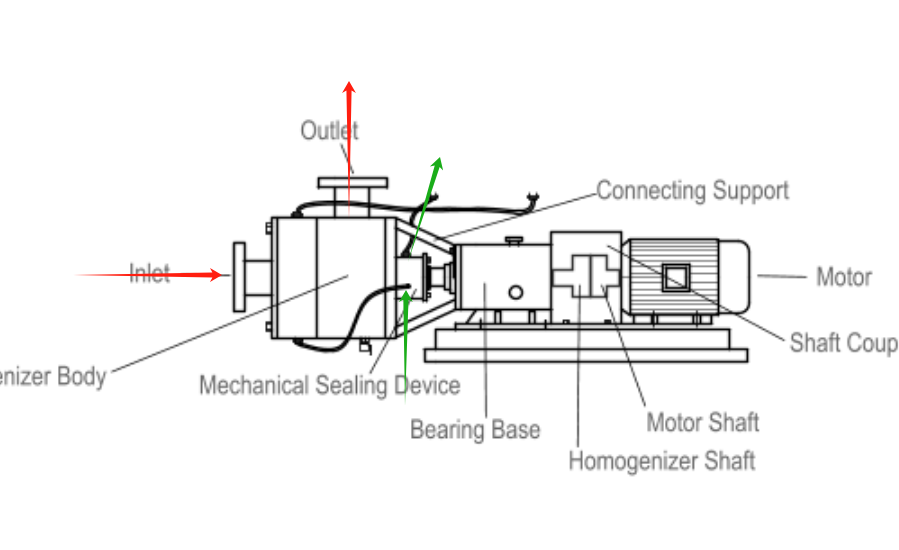

Working principle

The emulsifying pump drives the rotor to rotate at high speed through a motor, causing the material to undergo high-frequency shearing, centrifugal extrusion and friction collision in the gap between the rotor and stator. After adding the emulsifier, the immiscible substances are emulsified instantly. The multi-stage stator and rotor structure enables the material to undergo hundreds of thousands of shearing actions, significantly refining the particles

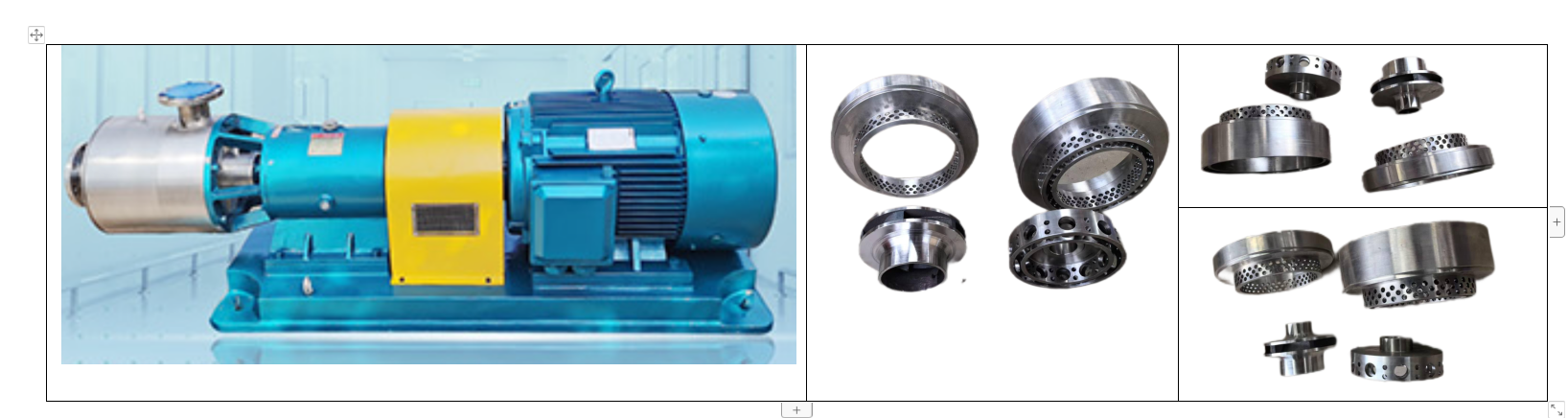

Structural characteristics

Broadcast

Rotor-stator assembly: The pump cavity contains 1-3 sets of multi-layer stator and rotor pairs that interlock. The number of stages affects the fineness of emulsification

Material: The outer pump cavity is made of stainless steel SS316, which is wear-resistant and not prone to rust. The internal pump cavity structure is more corrosion-resistant and wear-resistant, and can handle oxidizing liquids

Transmission design: The cantilever transmission shaft is connected to the motor through an elastic coupling. Inside the working chamber, there are three sets of stator and rotor

Functional characteristics

Realize the integration of grinding, dispersion and homogenization mixing

The modular structure is convenient for integrated installation

Eliminate quality differences between batches

It can handle high-viscosity materials without dead corners

Application field

Daily chemical industry: Cosmetics and detergent production

Food processing: Emulsification of chocolate and salad dressing

Pharmaceutical manufacturing: Preparation of injections and creams

Chemical engineering field: Petroleum, coating treatment

[contact-form-7 id=”706eeae” title=”Contact form 1″]